America Makes and the National Center for Defense Manufacturing and Machining (NCDMM) announced the winners of a recent project call awarded through the Office of the Under Secretary of Defense, Manufacturing Technology Office (OSD ManTech). The project call, Improvements in Manufacturing Productivity via Additive Capabilities and Techno-Economic Analysis 3.0 (IMPACT 3.0), consisted of two topic areas of focus and aims to demonstrate lead time, productivity, and yield improvements for casting and forging (C&F) manufacturing operations using additive manufacturing (AM) technologies.

The RPI-led project Adaptive Closed-Loop Control of Wire Arc Additive Manufacturing was awarded $1.5M for 18 months in the topic area of Wire Arc DED Process Sensing and Control. The RPI team is led by ECSE department head John Wen with the participation of MANE faculty members Johnson Samuel and Sandipan Mishra, Senior Research Engineer Glenn Saunders, and four ECSE and MANE doctoral students ((Chen-Lung Lu, John Marcotte, Jayden Smith, Rifat Bin Zakir). Partners on this project include GE Aerospace Research (Pinghai Yang, Laura Dial, Christopher Immer, Victor Ostroverkhov) and Wason Technology (John Wason).

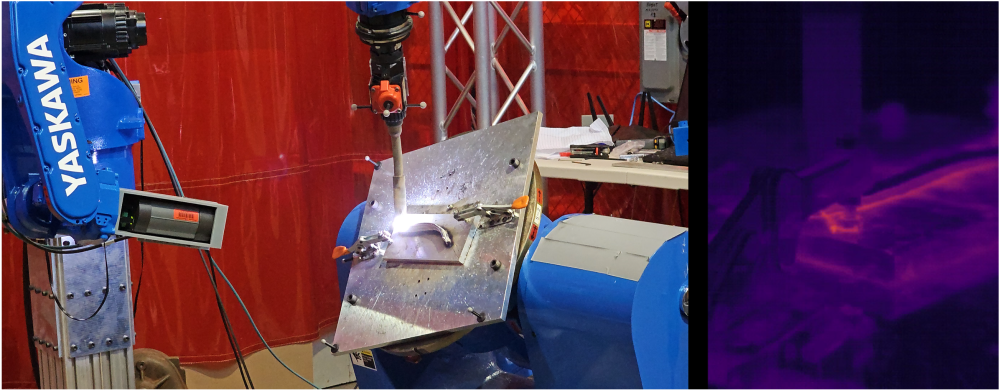

Wire arc directed energy deposition (DED) robotic additive manufacturing offers near-net-shape fabrication for aerospace components and the repair and modification of cast and forged parts. However, the inherent variability can compromise geometric accuracy and material quality, resulting in a greater burden during inspection and qualification. While in-process sensors have been introduced to mitigate these issues, they often require pausing the process, which limits productivity and adversely affects part quality, especially for large, heavy builds.

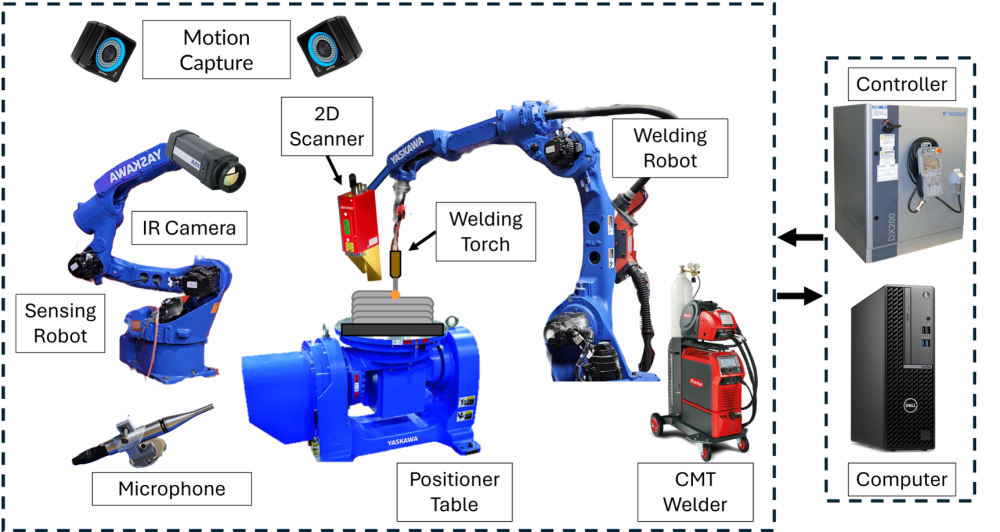

This project proposes a real-time, closed-loop control system that continuously adjusts both toolpath coordinates and deposition parameters during the build process, without halting operation. The system will integrate in-situ geometry and radiometric sensors to enable dynamic monitoring and adaptive control based on a hybrid physics-informed and data-driven process model. The proposed control technology will be applied to a representative DoD-relevant geometry, such as an engine case ring used in aircraft propulsion or turbine systems.